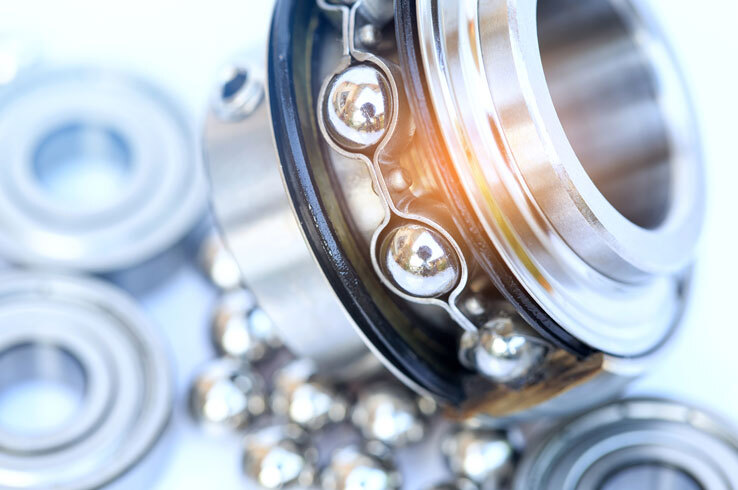

In today’s advanced manufacturing landscape, CNC machines – whether for milling, drilling, grinding, or cutting – are indispensable. Each type of CNC machine is designed for precision, speed, and reliability, but they all share a common feature: the need for high-performance bearings to deliver optimal performance. In this guide, we’ll explore how spindle bearings, particularly precision angular contact bearings, play a vital role across different CNC machines, helping manufacturers achieve the finest tolerances and smoothest operations.

Why Bearing Selection Matters in CNC Machinery

The efficiency and longevity of any CNC machine hinges on bearing quality. High-speed operations, varying load distribution, and the need for minimal vibration place a premium on the right bearings. This is where Precision Angular Contact bearings (often known as spindle bearings) excel. Built to handle both radial and axial loads with exceptional accuracy, these bearings ensure stability and precision, crucial for the demanding environments of CNC machining

Key Types of CNC Machines and Their Bearing Requirements

Rather than assigning specific bearings to each type of CNC machine, in this article, we will look into how Angular Contact and Spindle Bearings are used across various CNC machine types:

Milling Machines

Milling is all about precise cuts and detailed work, often involving high-speed rotations. Precision Angular Contact Bearings are often the best bearing to use for milling machines due to their ability to handle both radial and axial loads. Their accuracy enables the mill to maintain exact movements, which helps to ensure clean, accurate cuts even at very high speeds.

Drilling Machines

Drilling involves vertical and horizontal loads that require both strength and precision. Spindle bearings with high radial load capacities allow the drill bit to perform without wobbling, reducing the chance of deviations or rough edges. The precision offered by Angular Contact bearings is designed to enhance stability, which enables reliable, straight cuts.

Grinding Machines

Grinding is all about achieving the finest tolerances and finishes. The vibration-damping and load-bearing capabilities of precision spindle bearings are essential in grinding applications to ensure smooth operations, minimal vibration, and fine accuracy. By reducing heat generation and resisting wear, these bearings extend machine life and maintain product quality.

Cutting and Routing Machines

Cutting machines, particularly those in woodworking or metal fabrication, face complex load dynamics. Angular Contact bearings support these varied forces, ensuring the spindle can handle both light, fast cuts and heavier, slower operations. The adaptability provided by angular contact bearings plays a vital role in achieving smooth edges and accurate dimensions.

Benefits of Precision Angular Contact Bearings in CNC Machines

- High Precision and Stability

Essential for accurate movements, they help in maintaining consistent performance across different CNC processes.

- Reduced Vibration and Noise

Precision bearings minimise vibrations, which is crucial in maintaining quality, especially in grinding and milling.

- Enhanced Machine Longevity

Angular contact bearings are durable, extending the lifespan of CNC equipment by withstanding repeated stress and high loads.

- Heat Resistance

These bearings are crafted to manage heat efficiently, a key factor in high-speed operations that prevents component wear.

Choosing the Right Bearing for Your CNC Machine

Selecting the right bearing is crucial for ensuring optimal performance and longevity of your CNC machine. Below, we have listed some key considerations for selecting a CNC machine bearing.

Understand Your Machine's Requirements

Each CNC machine has different needs based on its operation. Users should make sure they consider the speed, load capacity, and forces acting on the bearing. Angular Contact bearings are ideal for handling both radial and axial loads in milling, drilling, and grinding machines.

Material and Coating

Select high-quality bearing materials such as steel or ceramic for better durability and load capacity. For harsh environments, consider bearings with protective coatings to prevent corrosion.

Operating Speed and Temperature

For high-speed operations, choose bearings that can withstand heat and maintain performance. Also, consider the lubrication needs of the bearing to reduce friction and overheating.

Precision and Tolerance

High-precision bearings are critical for CNC machines that require tight tolerances, such as in grinding or fine milling. Check the bearing's precision matches your machine's accuracy requirements.

Load Capacity

CNC machines experience varying load conditions, so choose bearings that can handle both radial and axial loads, with a focus on those with higher axial load capacity for heavy-duty operations.

Maintenance and Durability

Opt for bearings that require minimal maintenance, like sealed or shielded bearings, which protect against contaminants and retain lubrication. Proper bearing selection can reduce maintenance needs and extend machine life. At Quality Bearing Online, we stock only the world-renowned brands.

By carefully considering these factors, you can ensure your CNC machine operates efficiently and lasts longer. At Quality Bearings Online, we offer a wide range of precision bearings for all types of CNC machinery, and our expert team is available to guide you in choosing the best fit.

Trust Quality Bearings Online for Your CNC Needs

At Quality Bearings Online, we specialise in providing top-quality bearings to CNC operators worldwide. Our extensive range of precision bearings ensures you’ll find the right solution for your unique requirements. For more guidance about selecting the best bearings to enhance CNC machine performance, read our Ultimate Guide to High-Performance CNC Machine Bearings.

Need more advice? Contact us today to discover the bearings that best suit your CNC machines.